How the Oboe is Made

Assembly and adjustment

The pads are made of two different materials

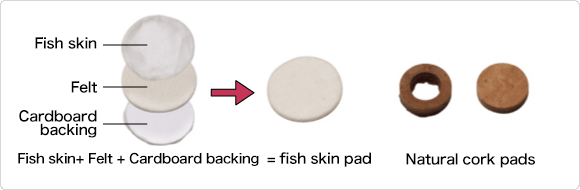

The oboe's small tone holes require equally small pads. Two materials are used to make the pads. Some are made from the same "fish skin" (actually, cattle intestine) as the pads of a clarinet, and some are made from natural cork. Each material is used in specific places.

Oboe pads made from two different materials.

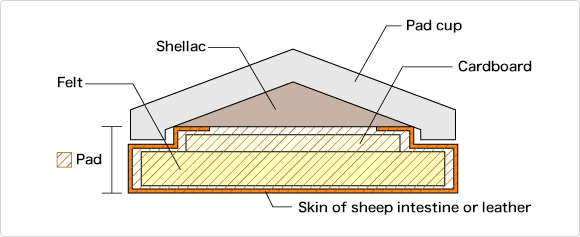

Cross-section of where a pad is affixed.

White shellac is the bonding agent

The bonding agent shellac is used to adjust the pads. There is both black and white varieties of shellac, with white being traditionally used for oboes. Because this form is more fluid and flows more easily than the black type, it is suited to making minor adjustments so that the pads are exactly flush with the tone holes.

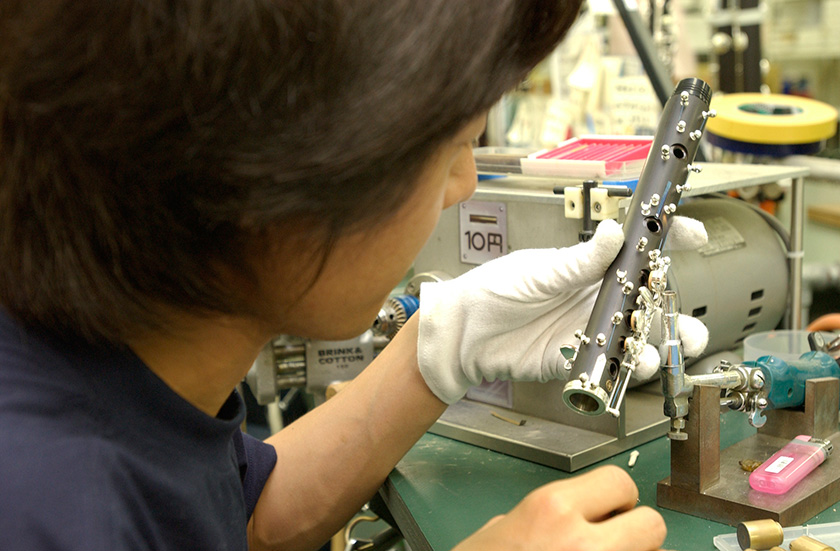

The nerve-wracking work of assembly and adjustment

Finally, there is the process of assembly and adjustment. The key posts are embedded, the parts forming the keys are incorporated into the bar-affixed pipe, and the pads are fitted on. Then, the motions among the keys are fixed using adjustment screws, and the instrument is complete.

Because the oboe has so many parts and they are all complexly interrelated, several days are required to assemble and adjust a single instrument. It is a very detailed, nerve-wracking task.

Musical Instrument Guide:Oboe Contents

Structure

How to Play

How the Instrument is Made

Choosing an Instrument

Trivia

- Why does the oboe lead the orchestra in tuning?

- Do the reeds have a front and a back?

- The keys recoil via springs!

- This is how the oboe and the cor anglais differ

- The charumera was the oboe's cousin

- You can reduce time spent breathing using circular-breathing techniques?

- The Wiener oboe that survived an existential crisis

- Oboe masterpieces: concertos

- Oboe masterpieces: chamber music

- What is the alto oboe?

- The heckelphone, which resembles the oboe

- The oboe is the bassoon's cousin