How a Trombone is Made

How the bell is made

Hammering it into shape makes it sound better

High quality bells start with the same process, whether for trombones, saxophones, or trumpets. For 1-piece bells (made using the traditional method of forming the bell from a single sheet of metal), the ends are sintered together, heated, washed in acid, then hammered into shape with a wooden mallet.

A cored bar that has been specially prepared for each model is used to shape the bell. This is by no means an easy task and requires the advanced skills of a craftsperson.

The craftsperson hammers the metal with a wooden mallet to form the bell

The sound of the bell changes completely as it is hammered into shape-which is actually quite strange as no major changes are noticeable in the metallic structure.

Left: Before bell shaping; Right: After bell shaping

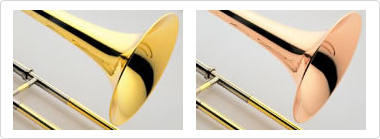

Bells come in two different colors

There are two types of materials typically used to make bells. One is yellow brass, which is similar in color to a Japanese five-yen coin, and the other is gold brass, which is closer to the color of a Japanese ten-yen coin. Although both materials are brass, their compositions are different. Gold brass is 85% copper and 15% zinc, while yellow brass is 70% copper and 30% zinc. They also sound different. Yellow brass has a bright and forceful timbre, while gold brass has a shiny and gentle timbre. Players generally choose a material based on whichever sound they prefer.

Left: Yellow brass; Right: Gold brass

Musical Instrument Guide:Trombone Contents

Structure

How to Play

How the Instrument is Made

Choosing an Instrument

Care and Maintenance

Trivia

- God is in the trombone

- The trombone was a bit of a problem for cavalries...

- A trombone that would scare even a snake!

- Two instruments, both tenor, but quite different!

- A trombone player walks into pawnshop...

- You can trill just by moving your mouth

- It is possible to increase the pitch even as you extend the slide

- Famous pieces from trombone concertos

- Orchestra pieces in which the trombone plays an important role

- The Yamaha quartet

- For trombones, why does sheet music notation differ from the fundamental tone of the instrument?

- A bass trombone-with an F attachment only