How a Drum is Made

Finally, a drum is born!

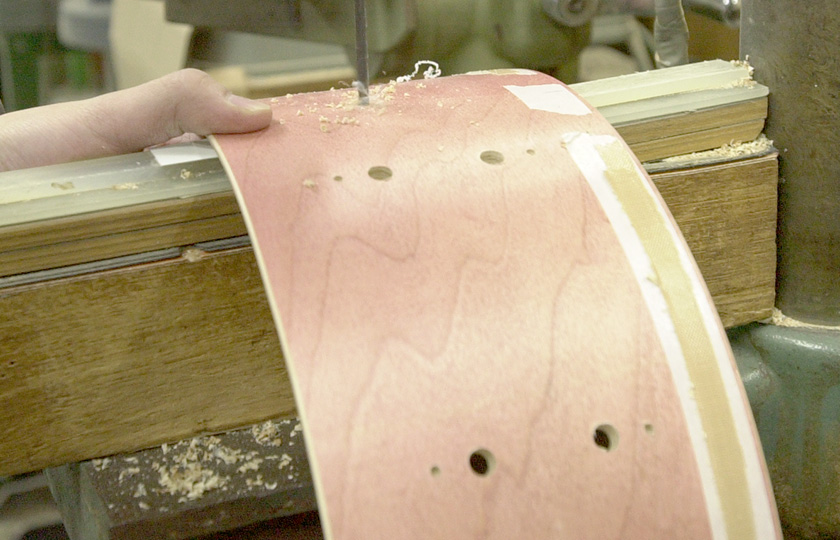

Shaving the ends of the shell

Here, the snare drum rims are processed. Up to this point, both ends of the drum have been flat, and in this condition they will not ring as they should, so the outer rim of the drum is shaved down to create a thin lip, called the "bearing edge," where the head is attached. The bearing edge has a special shape that makes it easier for the head to hug the drum.

This gives the oscillating body, the head, sharp fixed periphery conditions (called boundary conditions), so that vibration propagation loss is kept to a minimum.

The shell rim is carved into a bearing edge that transmits vibration easier.

Finishing process

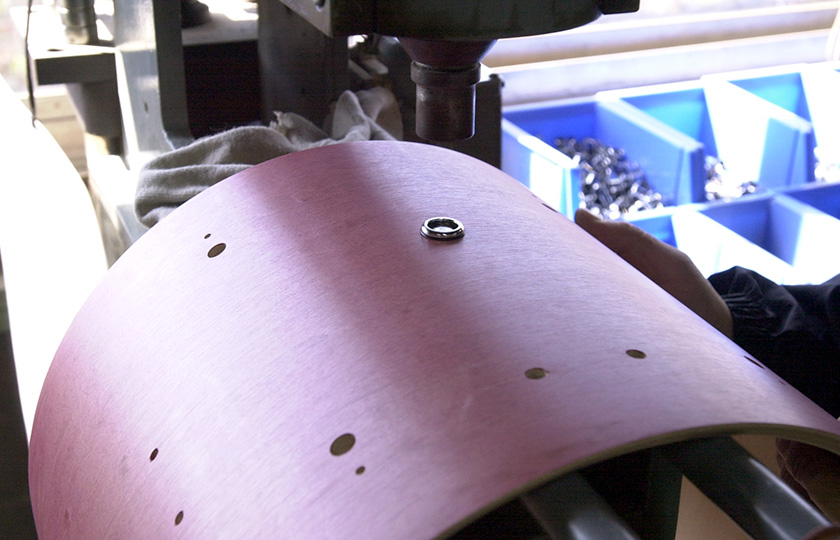

The bottom rim of the drum, where the snare attaches, is shaved into a gentle indent, and then the drum moves to the hole-drilling process. These holes are opened to accommodate the metal fittings, but these are kept as small as possible and as few as possible so as not to interfere with the shells resonant tone. Air holes are opened, and the necessary hardware attached.

Opening holes. The grain of the wood was used to give this drum a vintage finish.

An air hole with its fitting attached

Attaching hardware to a bass drum

The number of pieces of hardware attached will depend on the instrument and the type of lug nut, but the bass drum has between 180 and 200 pieces, while the tom-toms have between 120 and 300 pieces. The drummer will often change or replace parts, so care is taken when screwing in the bolt.

When the drum is shipped, the tension on the heads is neither too much nor too little. Large drums go without heads when in transit.

Assembling a snare drum

Final inspection is conducted with attention to the head tension.