How a Drum is Made

A beautiful finish

Polishing the wood before finishing

In the next stage, the shell is sanded to remove any adhesive from the surface and remove any uneven spots, which allows the paint to go on smoothly. Using makeup as an analogy, the face is scrubbed before foundation is applied, and any blemishes removed.

First, a machine is used to sand the wood. The sandpaper spins round and round, and it scrapes away the surface at the contact points. The inner and outer shells are each sanded many times, with the final sanding being performed by hand.

A sanding machine is used to sand the inside and outside.

The beautiful grain of a sanded shell

Paint, sand, and paint

Next is the painting process. The first coat of paint is applied, and then sanded, and the next coat is applied and sanded, and then the color is adjusted and the top coat is applied and given a mirror finish. Once the paint becomes hard, successive layers of paint will not stick to it, so before painting, the surface must be sanded to create fine scratches for the next application to adhere to.

On the first coat, the color of the paint is half that of the final color. A rag is used to apply the first coat, which brings out the grain of the wood.

The first stage of painting, a special coat of dark green is applied.

After the paint dries, a robot is used to apply the next coat to a precise thickness. A relatively thick paint is used to ensure that any pits in the wood are filled. This is then dried, and sandpaper is used to remove any bumps from the surface, after which paint is sprayed on and a decorative finish is given to the shell. There are a number of colors and finishing methods to satisfy a variety of finish preferences.

Paint is applied with a sprayer to give a flat black finish.

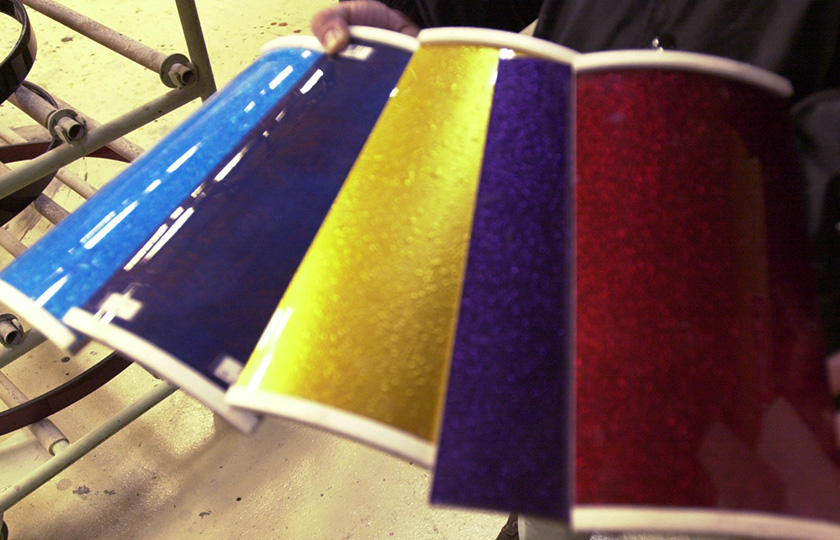

Color samples used to check the color when painting.

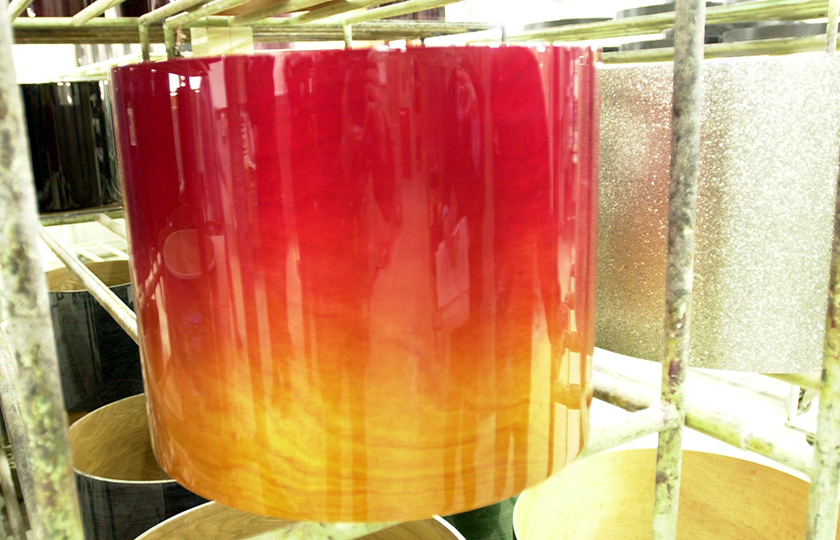

A shell with a sparkle finish

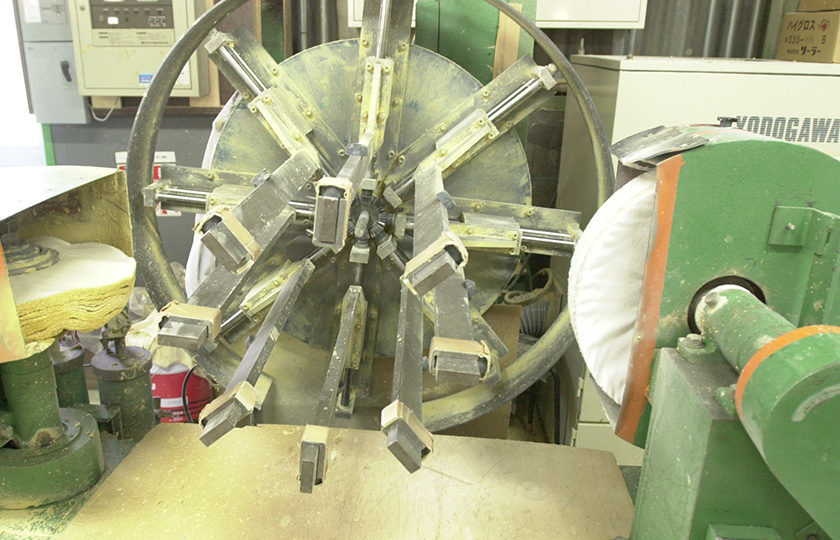

After painting, the shell is polished by machine, and then by hand. The shell is set in the center of this machine, and a vertical buffer comes from the right and a horizontal buffer comes from the left to buff the shell. The yellow buffing wheel is a rough buffer, while the white wheel is the finishing buffer.

The shell buffer

In the final stage, a master craftsman makes a detailed check and finishes the polishing. The buffer leaves characteristic buffing marks. The darker the color, the more noticeable the buffing marks are, and these must be removed in the final finish.

The shell is polished until you can see your face in it.

Shell with a matt red paint applied on a clear lacquer finish

UV paint is good for the tone as well as the color

The thinness of the exterior coating is as important as its beauty. The thinner the finish coating, the better resonance and sustain the shell will have. UV paint has a very thin coat, and so it is used for finishing.

UV paint hardens after several minutes of exposure to ultraviolet light, forming a UV coat. The ability to form several, thin, film layers lends depth to this type of finish. It also helps to reduce fading or discoloration. Some drums will become discolored from the weak rays of late-afternoon sun or florescent lights.

Complicated patterns are created with plastic

For patterns that are hard to create by painting, or for marching drums that are used outside, a polyester or polyvinyl chloride sheet is used. The patterns are created by applying three or more sheets.

Plastic sheets with complex patterns

The plastic sheets have an adhesive backing, so first a protective sheet is applied, and the shell is set on the machine. The shell is then rotated while the film is applied with high pressure.

The moisture-cured adhesive allows the plastic sheet to be removed easily if done immediately, but overnight, it becomes as hard as cement.

A protective sheet is applied to the outer and inner surfaces of the drum before being set in the machine