How the Clarinet is Made

Making the Body

The wood is allowed to dry for several years

Grenadilla, which is the raw material for the clarinet, is allowed to dry for several years. Both natural drying and kiln drying are used.

The processing of the body

Holes are cut in the dried rectangular wood using a machine and the wood is shaped by cutting the corners off.

Polishing the surface

The body is polished using Yamaha original oil in order to preserve the natural sound quality of the grenadilla and the texture of the wood, and to protect against cracks in the body due to the effects of moisture. After the surface has been treated, it is wiped clean of any excess oil.

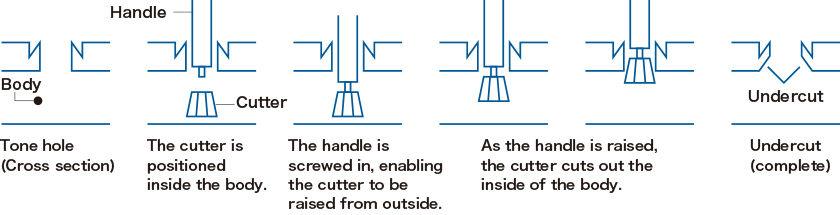

Putting in the tone holes

A machine is used to insert tone holes in the body and to cut out the inside of the body (this is known as undercutting). Since this process has a major influence on the timbre of the clarinet, the craftsman carefully makes fine adjustments by hand to produce a top-quality handmade model.

Putting in the tone holes

What is the undercut? The inside of the tone holes is beveled slightly, in order to give the instrument a more versatile feel.

Musical Instrument Guide:Clarinet Contents

Structure

How the Instrument is Made

Choosing an Instrument

Trivia

- "I Broke My Clarinet" is a French folk song

- Inspiring composers

- In Italy, a single B♭ clarinet

- At one time, most clarinets were made of boxwood

- In vogue in the 1900s-the metal clarinet

- A transparent clarinet?

- Famous clarinet works: concertos

- Famous clarinet works: chamber music

- What is the relationship between hertz and cents?