How a Violin is Made

Selecting the right piece of wood

Storing materials 24 hours a day, 365 days a year

The wood that will eventually be used to make a violin is stored in a temperature and humidity controlled room 24 hours a day, 365 days a year, to preserve the moisture in the wood.

Storing materials at a certain temperature and humidity before processing

A piece of spruce for the top plate cut cleanly with a hatchet along the grain

Top plate materials come from fir trees

Top plate materials come from the resonant and light, but hard, spruce tree, which is a type of pine tree in the fir family. The spruce looks like the type of fir trees that are used as Christmas trees. Strong pieces in which the fibers run straight are selected, and a hatchet is used to split it so that the fibers are not cut.

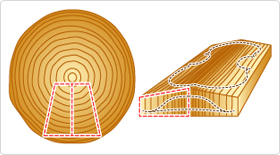

Matching two symmetrical trapezoids

When cutting material from a tree, the outer portion where the age rings are denser is cut thicker, which forms a trapezoid as shown in the diagram. When the left and right sides are put together, the outer portion, which is the hardest portion because of the denser age rings, falls in the middle, where the bridge is placed. This also makes the grain of the wood symmetrical, which means the vibration qualities are symmetrical as well.

Obtaining the top plate and bottom plate from a tree

Craftsmanship is also important!

Maple is used for the bottom and side plates because of its beautiful wood grain pattern. Practical considerations are not the only concern. Craftsmanship is also important.

Musical Instrument Guide : Violin Contents

Origins

Structure

How to Play

How the Instrument is Made

Choosing an Instrument

Care and Maintenance

Trivia

- The f-hole used to be a C-hole or S-hole

- Why the f-hole?

- Violinists must bow to the horse

- Steel strings or gut strings? That is the question

- Is the chinrest the unsung hero of the violin?

- Most violin varnishes are also medicines

- Violin masterpieces: Solos I

- Violin masterpieces: Solos II

- Violin masterpieces: Solos III

- Violin masterpieces: Concertos I

- Violin masterpieces: Concertos II

- Viola masterpieces: Chamber music

- Viola masterpieces: Concertos

- Cello masterpieces: Concertos I

- Cello masterpieces: Concertos II

- Cello masterpieces: Solos

- Contrabass masterpieces: Concertos

- Contrabass masterpieces: Chamber music

- Orchestral masterpieces featuring the contrabass

- What do you call the part on the bow that you hold?