How a Violin is Made

Shaping the ideal tone

The roundness of the body requires a craftsman's skill

The body of a violin is rounded, and in fact, the thickness of the wood is not uniform either. Both the shape and the thickness describe a gently curving line. This lack of a straight line as a point of reference makes it very difficult to accurately shape. Thus, shaping is normally left to the judgment of an experienced craftsman.

The thickness of the bottom plate also varies, so that its surface forms a curved line.

Yamaha's shaping method

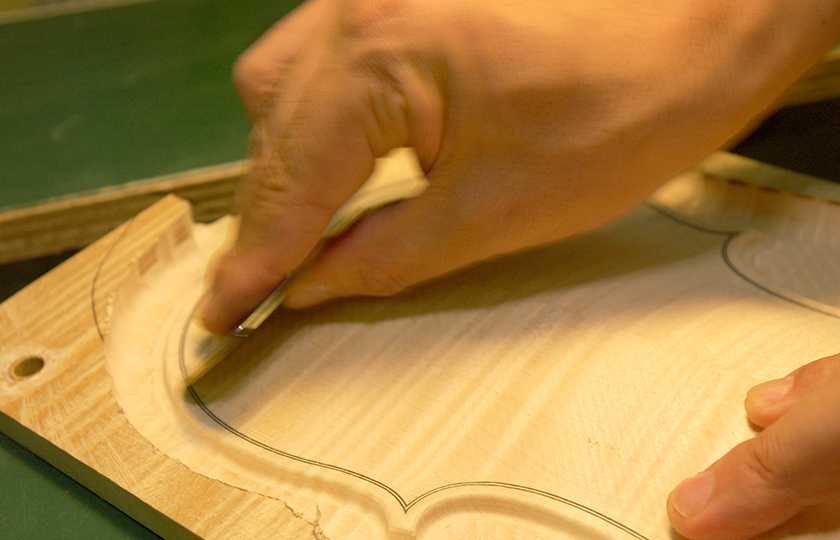

Using a scraper to remove bumps from the top plate

The ideal shape for both the top and bottom plates are stored as three-dimensional data in a computer. This data is used in a high-precision technology called numerical control (NC) processing, which shapes the wood. After an initial rough shaping, a groove is carved around the edge and purfling, a three-ply piece of wood with black, white, and black plies, is inserted by a craftsman. Then, NC processing is applied again to complete this stage of the shaping. This is not, however, the end of the shaping process. In the end, a craftsman uses a scraper to remove the 0.1 mm bumps that remain on the surface of the top plate.

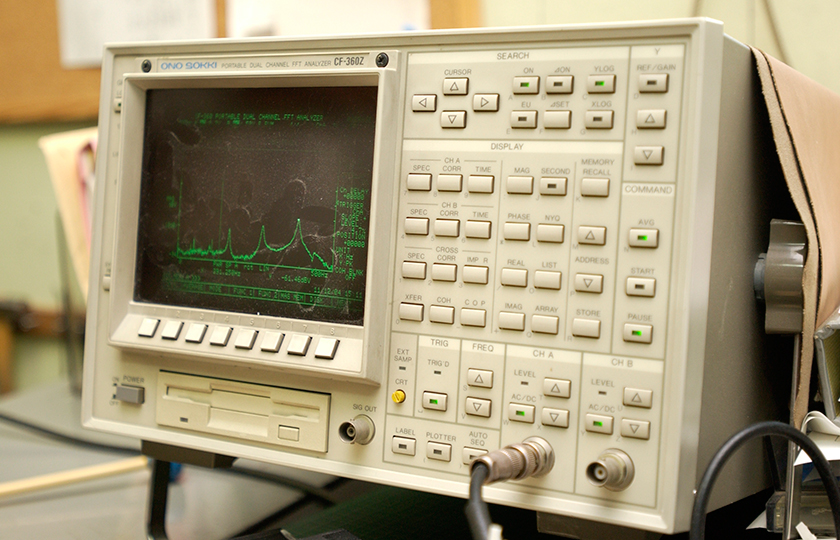

In order to obtain the best tone from the wood, the tonal qualities of the top and bottom plates are measured during the shaping process. This process is repeated during the attachment and shaping of the bass bar on the top plate.

To measure the tonal qualities of a piece, a craftsman knocks on the piece in front of a special measuring device. The frequency and volume of the sound thus produced is instantly shown as a graph on the display. If the wood is hard or light, the tone is higher, and if the wood is soft or heavy, the tone is lower. The graph will change depending on the characteristics of the wood, and this is used as a reference during the shaping process.

Tone measuring device: The x axis shows the frequency, the y axis shows the volume

Creating the curved side plates

Pre-bending a side plate with an iron

The scroll is at the very top of the neck. The scroll is intended to look like a rolled up strip that is narrower in the middle. The craftsman's skill is demonstrated in the symmetry of the scroll. When the necks of older violins need to be replaced, often times the scroll and the body are kept, and the central part of the neck alone is replaced.

The highpoint of craftsmanship: the scroll

The scroll is at the very top of the neck. The scroll is intended to look like a rolled up strip that is narrower in the middle. The craftsman's skill is demonstrated in the symmetry of the scroll. When the necks of older violins need to be replaced, often times the scroll and the body are kept, and the central part of the neck alone is replaced.

The scroll is carved to look like a rolled up strip that is thinner in the middle

Musical Instrument Guide : Violin Contents

Origins

Structure

How to Play

How the Instrument is Made

Choosing an Instrument

Care and Maintenance

Trivia

- The f-hole used to be a C-hole or S-hole

- Why the f-hole?

- Violinists must bow to the horse

- Steel strings or gut strings? That is the question

- Is the chinrest the unsung hero of the violin?

- Most violin varnishes are also medicines

- Violin masterpieces: Solos I

- Violin masterpieces: Solos II

- Violin masterpieces: Solos III

- Violin masterpieces: Concertos I

- Violin masterpieces: Concertos II

- Viola masterpieces: Chamber music

- Viola masterpieces: Concertos

- Cello masterpieces: Concertos I

- Cello masterpieces: Concertos II

- Cello masterpieces: Solos

- Contrabass masterpieces: Concertos

- Contrabass masterpieces: Chamber music

- Orchestral masterpieces featuring the contrabass

- What do you call the part on the bow that you hold?