How a Bassoon is Made

How the Bocal is Made

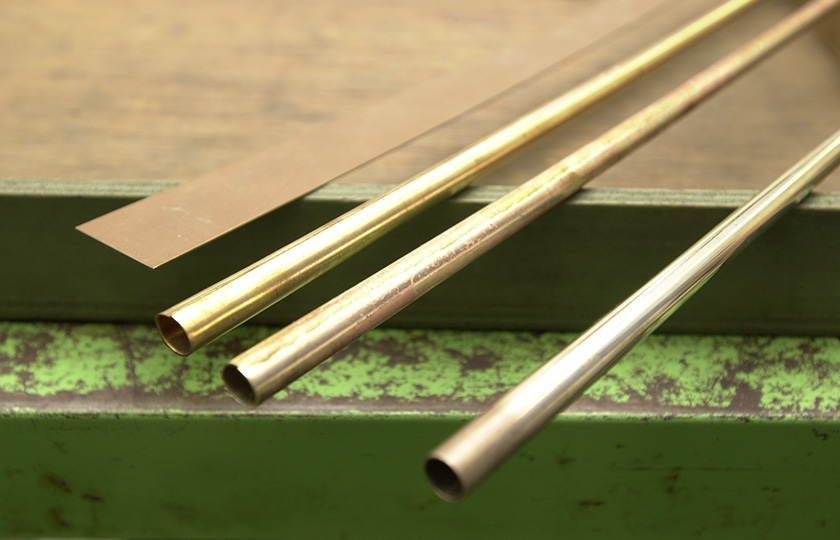

Conical tube made from flat metal sheet

Let's take a look at the traditional technique for making the bocal.

First the sheet is prepared, cut into the shape of a trapezium. Then it is bent inwards from both sides, and solder applied to the join. When heat is applied the solder melts, and binds the two sides.

Next, the shape is squashed so that the seam is flattened, and the tube is then pulled lengthways to produce a narrow, conical tube as per the design. After that, a rod is inserted to prevent the tube from being crushed, and the stamp is engraved.

From rear, the sheet, after applying solder, after the seam is flattened, after stretching

The stamp is engraved carefully on each bocal, one by one

The clearly engraved stamp (finished product)

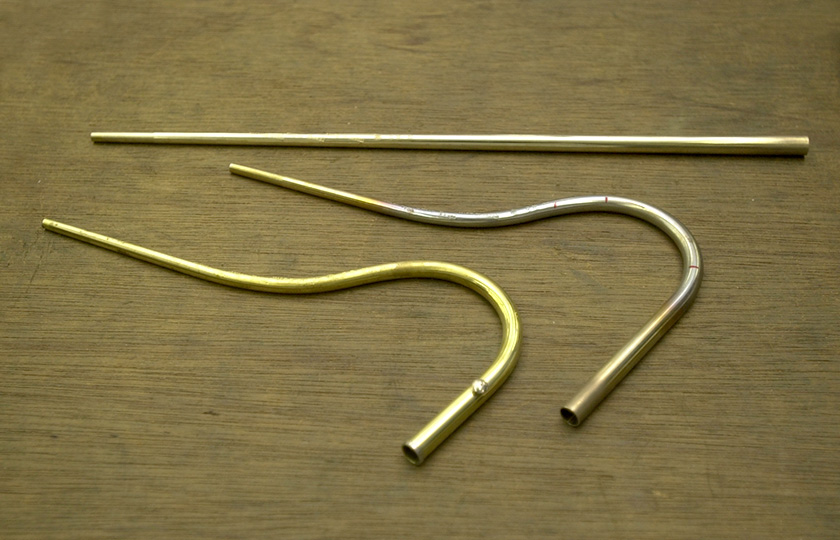

Curve formed in two stages

The conical tube used to make the bocal is heated using a burner to make the metal soft, then a low-temperature solder is applied to the interior and the tube is bent. As the bocal is curved in two directions, the curves are formed in two stages.

Thin, conical tubes after heating and bending

Musical Instrument Guide : Bassoon Contents

Structure

- What Kind of Musical Instrument is a Bassoon?

- A Long Tube that can be Separated

- The Bocal and its Various Functions

- Unique Features of the bassoon, and How to Play

- [Experiment1]Comparing the Sound of Tone Holes cut Obliquely and Perpendicular

- [Experiment2]Encasing the Bore in Various Materials

- Bonus Experiment

How to Play

How the Instrument is Made

Choosing an Instrument

Trivia

- An Instrument that is Sensitive to Humidity

- Sounds from water in the U-tube?

- There's a needle in the bocal?!

- Comments by conductors caused popularity to tumble?

- Bassoon classics - Chamber music works

- Bassoon classics - Concertos

- Is the "contra-fagotto" a contrabassoon?

- What is the best tool to file a reed?