How a Trumpet is Made

Manufacturing the valve casings

The valve casings represent the heart of the trumpet

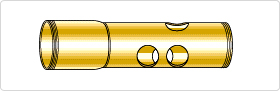

The tube which moves the piston up and down is called a valve casing. The valve casing is the key component which acts as a switch, changing the pitch of the note—in a sense, it is the heart of the trumpet. All production work for the valve casings must meet the highest standards of precision.

1. Machining and broaching

Holes are drilled in precise locations.

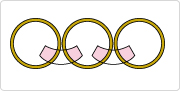

2. Brazing process

The components of the valve casing are fitted into a special jig and then passed through a kiln to braze them together in precise fashion.

Note: Brazing is a method for joining—like soldering—but uses a much higher melting point and produces extremely strong joints.

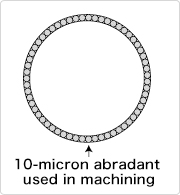

3. Boring

The interior of the brazed valve casing is precisely machined using a lathe. This machining work is a critical process in the production of instruments that use pistons.

The gap between the side of the valve casing and the piston is defined as 10 microns. This represents such high precision that a single human hair in the gap will stop the piston from moving.

*10 microns (0.01 mm) is approximately one-tenth the thickness of a single strand of human hair.

Musical Instrument Guide: Trumpet Contents

Structure

How the Instrument is Made

Choosing an Instrument

Care and Maintenance

Trivia

- Trumpeters in Bach's time alternated between instruments with a variety of ranges when performing

- The keyed trumpet-the fruit of the evolutionary process

- Famous trumpet works—Concertos, part 1

- Famous trumpet works—Concertos, part 2

- Famous trumpet works—Solos

- Is a Flugelhorn a horn? Or a trumpet?

- The highest note a trumpet can produce

- Aida trumpets for the Grand March

- The secret of the trumpet's traditional tone: small impurities!?