How a Trombone is Made

The slide must be straight-no exceptions!

At 70 cm long, a curve of even 0.2 mm is unacceptable!

The slide of a trombone is a straight piece of tubing that is roughly 70 cm long and quite thin (0.25 mm thick). The gap between the outer slide and inner slide has a radius of only around 0.1 mm. Therefore, in order for the tubing to slide smoothly, all four pipes (two for the outer slide and two for the inner slide) must be perfectly straight and parallel. For a 70 cm tube, an end-to-end curve of even 0.2 mm would render it useless.

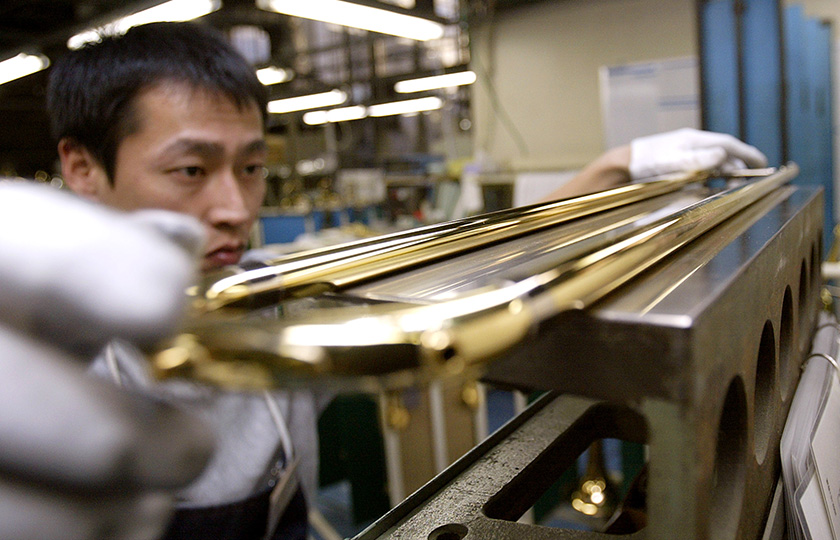

The outer slide and inner slide are gold and silver in color, respectively

The process whereby a precision tube is created is called "tube drawing." The photo below shows an inner slide being made. The shiny silver tube is the inner slide.

Silver-colored brass (a copper and zinc alloy) is used to create the outer slide of a trombone, while a metal that combines brass and nickel called "nickel silver" is used to create the inner slide.

A precision tube puller creating a straight tube

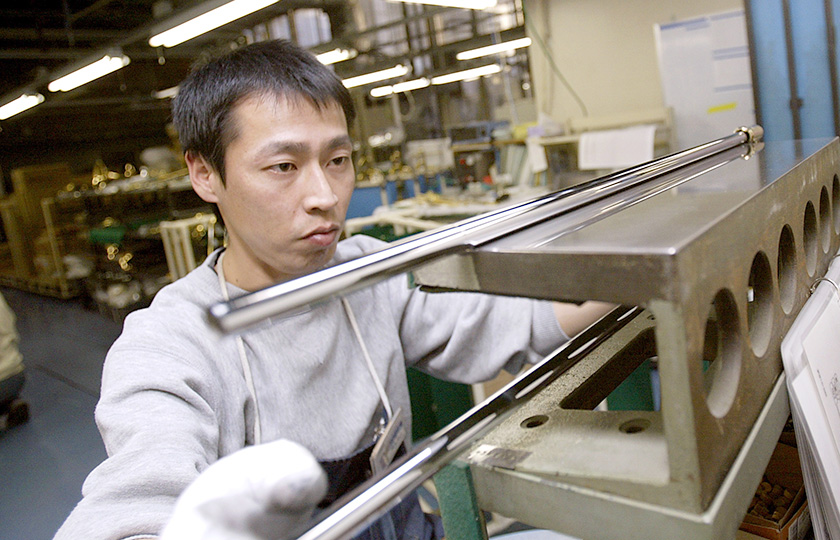

The finish is finely adjusted by a craftsperson

After the slide has been manufactured by an ultra-precise machine, a craftsperson visually checks the piece. He or she uses a tool called a surface plate to make sure the pipes are straight and parallel.

If they are warped, the craftsperson will then apply a subtle amount of force by hand to bend it into shape. This work requires the skill of an experienced craftsperson.

Checking that the outer slide is parallel

Checking that the inner slide is straight

Checking that the slide moves smoothly

Musical Instrument Guide:Trombone Contents

Structure

How to Play

How the Instrument is Made

Choosing an Instrument

Care and Maintenance

Trivia

- God is in the trombone

- The trombone was a bit of a problem for cavalries...

- A trombone that would scare even a snake!

- Two instruments, both tenor, but quite different!

- A trombone player walks into pawnshop...

- You can trill just by moving your mouth

- It is possible to increase the pitch even as you extend the slide

- Famous pieces from trombone concertos

- Orchestra pieces in which the trombone plays an important role

- The Yamaha quartet

- For trombones, why does sheet music notation differ from the fundamental tone of the instrument?

- A bass trombone-with an F attachment only